| ˇˇ

|

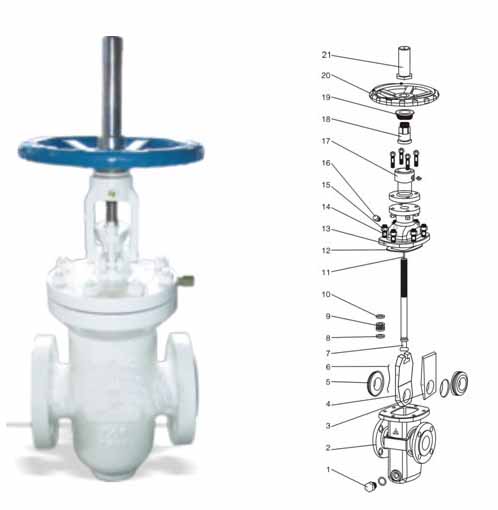

NEWTON VALVEis one of the leading and professional Through Conduit Gate Valve or Flat Plate Gate Valve, Parallel Plate Gate Valve Manufacturer in China. NEWTON VALVE Through Conduit Gate Valves or Flat Plate Gate Valves are designed and manufactured strictly to DIN, BS, ANSI, API, ISO & GB Standards

Materials available in Cast Carbon Steel, Stainless Steel, Duplex and Special Alloys

Size Ranges from 2ˇ±NB to 50ˇ±NB

Pressure Ratings from ANSI #150 to ANSI #2500

Ends connections available in Flanged, Butt welded, Hub-connectors, Compact Flange or Other Proprietary Connections

Operations in Handwheel, Gear, Pneumatic, Hydrau-Pneumatic and Electric etc.

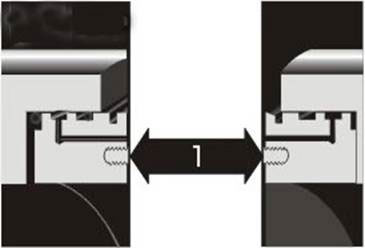

When the Through Conduit Gate Valve inside Pressure is similar or equal, the gate is under closing status, and the seat surface PTFE Sealing Ring forms an initial sealing (1), when the gate valve is on/off every time, the seat ring can clean the both sides of gate. (See Diagram 1 below)

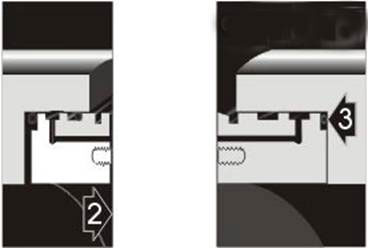

Enforcing all line pressure (2) onto the through conduit gate valve, the pressure acted onto the gate, forcing it against PTFE Ring of Outlet Seat. Compressing it until the gate is stopped onto the steel seat to form a double sealing: the first sealing is PTFE to Metal, the second sealing is metal to metal, meanwhile, the seat is also firmly forced into its recess. The O-ring (3) prevent any downstream flow at this point. (See Diagram 2 below)

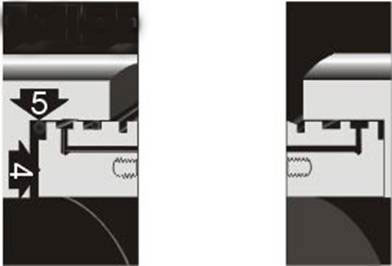

Inlet sealing is formed after the cavity pressure is released; pipeline pressure is acted onto the inlet seat (4) making it move toward to the gate which forms the PTFE to Metal sealing. Meanwhile, O-ring (5) and seat recess forms a compact sealing. (See Diagram 3 below)

The through conduit gate valve release its excrescent pressure, when the cavity pressure is more than pipeline, inlet seat is pushed toward to its recess because of thermal expansion, the cavity excrescent pressure between seat and gate releases to pipeline. (See Diagram 4 below)

Through Conduit Gate Valve Structure Features

The Body structure is divided into casted and welded 2 types

The Seat is adopted by floating type structure with O-ring sealing and Pre-tightening force, making the valve with a inlet and outlet double sealing, meanwhile, the on/off torque of this structure is only half of some other standard valves which makes the through conduit gate valve can be easily on/off.

The seat using a sealing with PTFE Inserted which has a double sealing function of PTFE to Metal and metal to metal. The PTFE sealing surface has also another function to clean the dirt of the Gate.

Metal to Metal seated Through conduit Gate Valve Outside is equipped with a grease injection device, Grease passes through injection device and seat into seat sealing surface to make this type of valve realized a Zero Leakage.

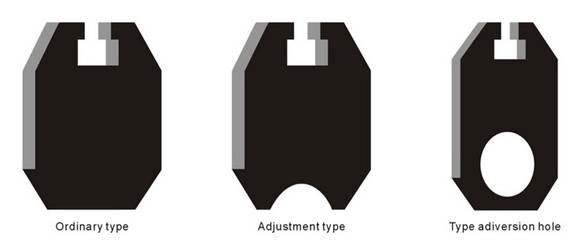

Through conduit gate valves with adversion hole, it is always fitted with the sealing face to protect itself destroyed by the medium no matter it is fully opened or closed which extended the service life accordingly.

When the through conduit gate valve is fully opened, the channel is smoothly to a linear, with a very small Cv and without any pressure loss to make the line can be cleaned by hair-ball through it.

The through conduit gate valve using a self-sealing type packing structure, it is not necessary to be frequently adjusted, and it is very easy or convenient for opening and closing, meanwhile, there is a secondary sealing grease injection device on the packing gland to ensure a reliable sealing function, a ˇ°Zeroˇ± leakage can be really realized, the problem of leakage from packing gland has been full erased compare with other standard types of valve.

Automatic removal of high pressure in the cavity when the through conduit gate valve is closed (See the working principle diagram for details) to ensure a safety operation.

With fully closed structure and perfect protection features which make the through conduit gate valve can meet the requirements of 24-hour duty.

An indication rod or viewing window is equipped with rising stem through conduit gate valves so that the on/off condition can be easily indicated, while, an enclosed gear rotating on/off indication device is equipped with a rotating stem type valve.

External surface of the directly built-in through conduit gate valve is corrosion-resistance with epoxy coated which can be with a same service life as its serviced pipeline system.

Through Conduit Gate Valve Flow Characteristics

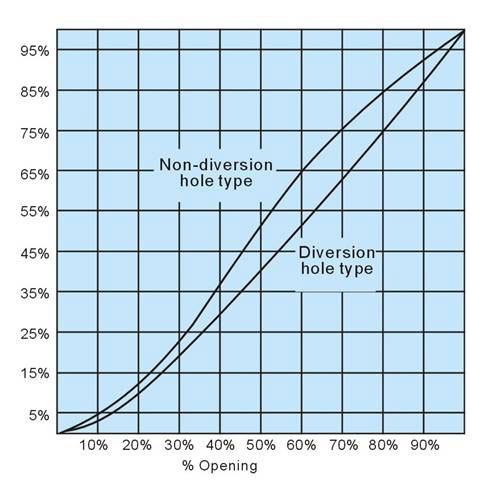

Through conduit gate valve with a diversion hole is equal to that of pipelines of the same specification whose characteristics is shown per hereunder per centum diagram.

Through conduit gate valve without a diversion hole with a cavity fly span smaller than that of wedge type gate valves, and it is regularly cylindrical object. Therefore, characteristics of the valves are similar except that they have a large pressure loss, further more, their flux adjustment behavior is better than that of the valves with a diversion hole. (See below diagram for detailed information)

Different types of Gate Shown and selection

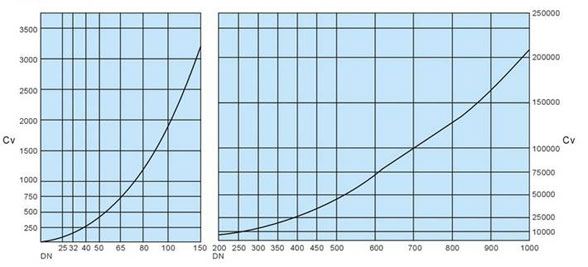

DN-Cv Graph for Through Conduit Gate Valves with Diversion Holes

|

ˇˇ |